Fuel Pump: 99 Tahoe; May 2018

- Kurt Reynolds

- Sep 1, 2020

- 2 min read

Updated: Sep 14, 2020

I replaced the fuel pump module on my 99 Chevy Tahoe with a 5.7L in May and June of 2018. I did so not because the fuel pump had completely failed and the vehicle didn't start, but because this pump was the original (19 years old) and because I broke off one of the fuel pump module nipples when I was trying to diagnose a long-crank condition. Side note: the long-crank condition only happened when the engine was warmed up leading to only a few possible causes such a faulty fuel pressure regulator or bad check ball in the fuel pump. If you are interested in knowing how to diagnose an extended crank or other fuel related issues, Eric O. at South Main Auto channel has some good videos to watch.

Repair

Later models of the Tahoe already have a fuel pump access panel designed into them when the vehicle is manufactured. However, the '99 Tahoe did not. Therefore, I implemented this feature into my Tahoe. Care must be exercised when cutting metal or welding around flammable liquids such as gasoline. A fuel tank is at its safest (not to be confused with safe) point when it is completely full of fuel or water. When a fuel tank is empty or more than halfway empty is when it is at very volatile potentials. Continuing on, I was very nervous during the cutting and grinding process and had a fire extinguisher located a few feet from the vehicle just in case one of the o-rings on one of the fuel lines was not sealing properly.

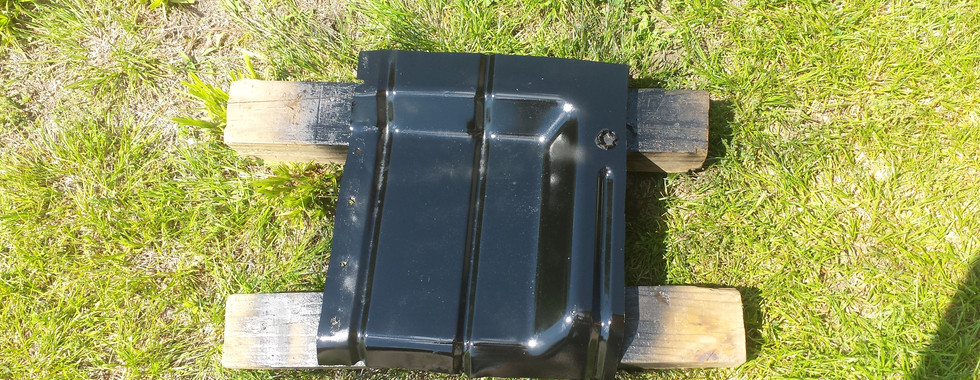

After cutting the square-ish pan section out, I bought some flat iron, weatherstripping, hold-down tabs, and paint to make the project look more professional. I cut the flat iron into pieces to make a shelf or mount for the pan; securing the flat iron to the vehicle's sheet metal with rivets. The weatherstripping was installed around the outside of the pan to reduce noise and seal the inside from the outside of the vehicle, albeit the carpet and insulation pad would provide most of the insulating characteristics.

A special tool is required to disconnect the lines from the pump. Then, a punch or flat-head screwdriver can be used in conjunction with a sledge-hammer to remove the outer ring by tapping it off in a counter-clockwise direction. Installation is the reverse of removal. Note: a new o-ring located under the metal ring should be used. This o-ring usually comes with a new fuel-pump module but I'm uncertain if one is included with just the fuel pump.

Comments